Durable Medical Instrument Parts: A Guide for the Manufacturing Industry

Release time:2025-06-11

In the realm of manufacturing, particularly in the mechanical processing and hardware fabrication sector, the term "durable medical instrument parts" holds considerable importance. These components are crucial in the production of medical devices that must withstand rigorous use while maintaining high performance and safety standards. Understanding the characteristics and production methods of the

In the realm of manufacturing, particularly in the mechanical processing and hardware fabrication sector, the term "durable medical instrument parts" holds considerable importance. These components are crucial in the production of medical devices that must withstand rigorous use while maintaining high performance and safety standards. Understanding the characteristics and production methods of these parts is essential for manufacturers aiming to cater to the medical field.

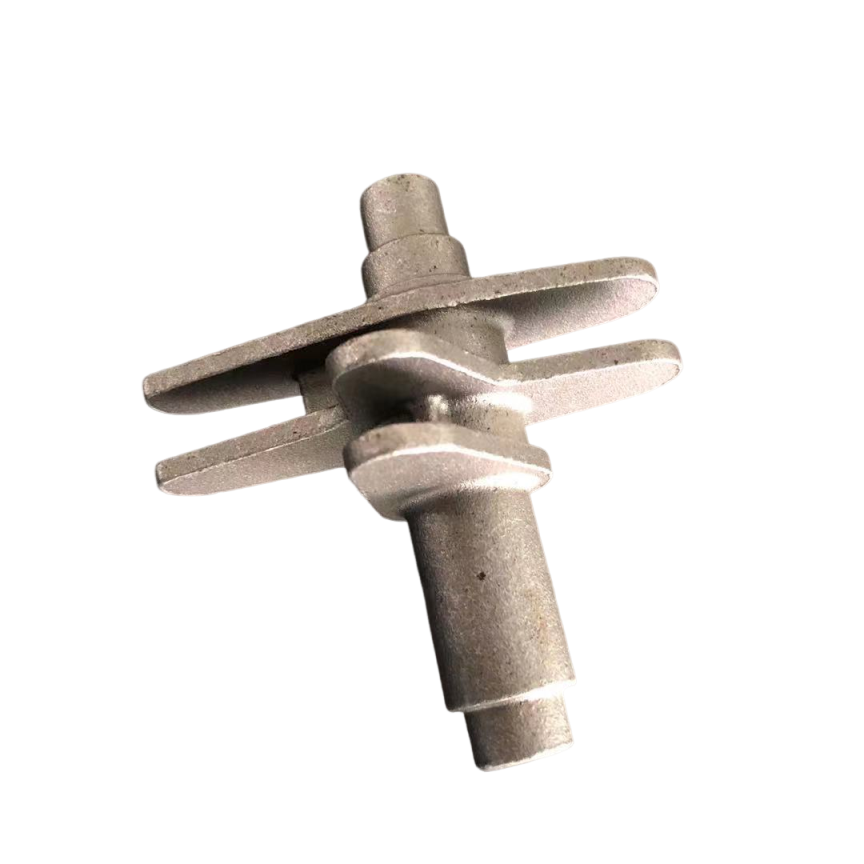

Durable medical instrument parts are designed to endure the demanding conditions of healthcare environments. These components are often made from high-quality materials that offer resistance to wear, corrosion, and other forms of degradation. Common materials include stainless steel, titanium, and certain specialized polymers. The choice of material is critical since it not only affects the longevity of the instrument but also its compatibility with various sterilization processes essential in healthcare settings.

One of the significant aspects of durable medical instrument parts is their precision. The manufacturing processes used to create these components often involve advanced techniques such as CNC machining, injection molding, and additive manufacturing. Each of these methods ensures that the parts meet strict tolerances and specifications, which is vital in medical applications where the reliability of instruments can directly impact patient outcomes.

Another factor to consider is regulatory compliance. Medical instrument parts must adhere to stringent regulations and standards set by healthcare authorities to ensure safety and effectiveness. This includes thorough testing and validation processes that verify the functionality and durability of each part. Manufacturers must stay updated with these regulations to ensure their products meet the necessary quality assurance benchmarks.

Moreover, the role of durable medical instrument parts extends beyond manufacturing. These components also contribute to the overall efficiency and effectiveness of medical procedures. For instance, durable surgical instruments can lead to enhanced precision during operations, reducing the risk of complications and improving recovery times for patients. This makes it imperative for manufacturers to prioritize quality and durability during production.

Lastly, ongoing innovation in materials science and engineering continues to shape the future of durable medical instrument parts. Advances in technology may lead to the development of even more resilient materials and smarter manufacturing processes, paving the way for superior medical devices. Manufacturers who embrace these innovations will likely find themselves at the forefront of the industry, providing high-quality, reliable products that meet the evolving needs of healthcare professionals.

In conclusion, durable medical instrument parts are a fundamental element of the manufacturing process within the medical device industry. By focusing on quality, precision, and regulatory compliance, manufacturers can produce components that not only meet the needs of healthcare providers but also enhance patient care outcomes. Understanding the intricacies of these parts is vital for anyone involved in the mechanical processing and fabrication of medical devices.