Aluminum Alloy die Cast

Custom Cast Aluminum alloy die casting Parts are metal components that are molded by high-pressure rapid injection molding. It has multiple advantages such as light weight, high strength, and high modeling complexity. Whether you are focused on product performance, production efficiency, or cost control, aluminum alloy die casting is a reliable choice. We are committed to providing you with high-quality die-casting solutions to make product manufacturing more efficient, stable, and competitive.

Category:

Automotive Parts

key word:Die casting

I want to consult

Product Description

Aluminum alloy die casting is a metal component that is molded by high-pressure rapid injection molding. It has multiple advantages such as light weight, high strength, and high modeling complexity. We use high-quality aluminum alloy materials and use advanced die-casting technology to make the products have excellent dimensional accuracy and surface finish, while taking into account good mechanical properties and corrosion resistance. Whether it is a thin-walled structure or a shape with complex details, die-casting technology can achieve one-piece molding, improving product consistency and overall strength.

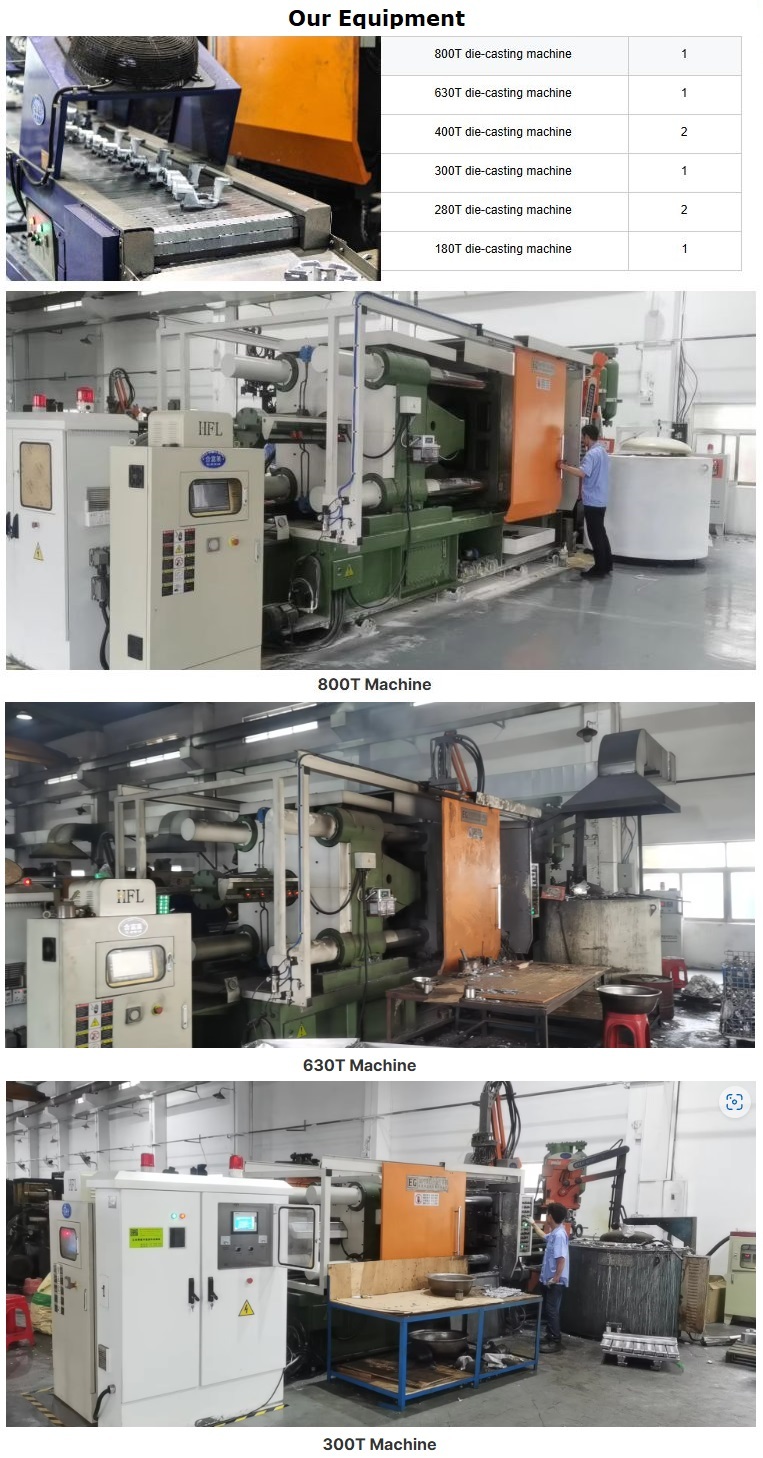

Yuanfei can offer a comprehensive one-stop solution covering product design, mold making, die casting, machining, CNC precision processing, and surface finishing. With over a decade of experience in OEM casting manufacturing, we are a dedicated and reliable partner known for consistent product quality and competitive pricing.

Our Casting Advantages:

Yuanfei Metal maintains strict control over every stage of the production process to ensure that each die-cast product consistently delivers reliable structural integrity and superior surface quality. Thanks to the lightweight nature and excellent thermal conductivity of aluminum alloy, these castings are ideal for applications requiring reduced weight and efficient heat dissipation. Through precision mold engineering and advanced high-pressure casting techniques, the resulting products not only feature a refined appearance but are also well-suited for subsequent machining and processing. Aluminum alloys inherently possess low density, excellent thermal conductivity, and strong corrosion resistance. When combined with the die-casting process, they can significantly improve component strength and service life while achieving lightweighting. This is particularly important for products requiring high durability, heat dissipation, and aesthetics.

In terms of customer value, aluminum alloy die casting not only reduces processing costs and minimizes post-processing, but also enables integrated molding of complex structures, providing greater flexibility in product design. High mass production efficiency and long die life make it particularly suitable for industrial applications requiring high consistency.

2. Provide a personalized formula according to customers' special drawing requirements.

3. Manufacturers with strong production capacity ensure fast production after order confirmation.

4. Protect the sales area and personal information of all customers..

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Previous page

Next page

Previous page

Next page

Related Products

Do you have any questions?

We will contact you within one working day. Please pay attention to your email.