China lost wax Casting Factory investment Casting Foundry 316l Stainless Steel Silica Sol investment Casting parts

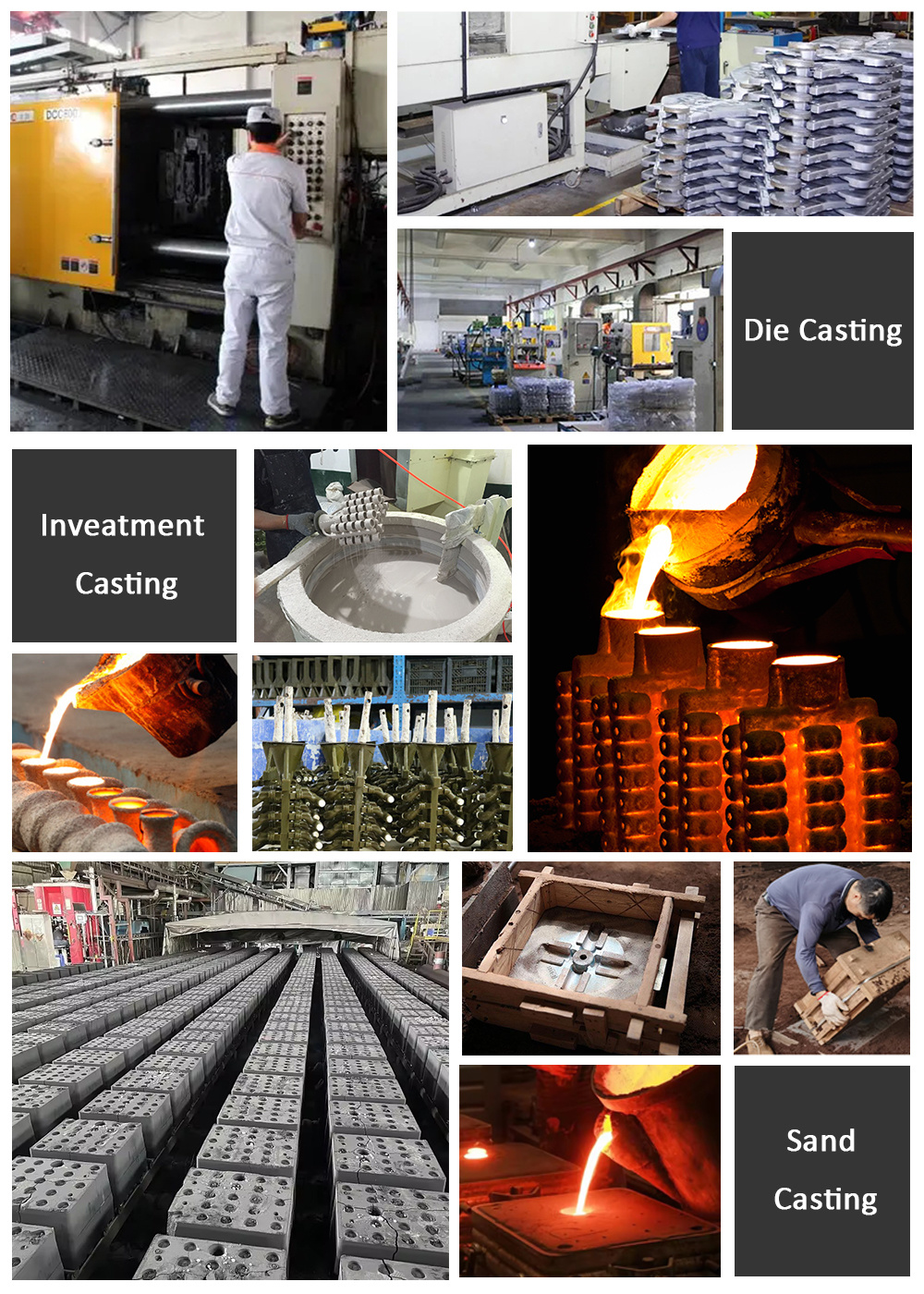

Our factory specializes in the production of die castings, castings and sand castings made of different metal materials. Our experienced team of engineers and technicians are able to handle complex mold design, process optimization and quality issues. The mature production lines ensure efficient production and high-quality products. Strict quality control from raw material procurement to finished product delivery ensures that every link meets customer requirements and industry standards. With flexible production capabilities, we can quickly respond to customer needs, provide customized solutions and shorten delivery cycles.

Category:

Household Metal Parts

key word:Die casting

I want to consult

Product Description

| Product name | China lost wax Casting Factory investment Casting Foundry 316l Stainless Steel Silica Sol investment Casting parts |

| Quotation | According to your drawing(size, material, thickness, processing content, and required technology, etc) |

| Tolerance | +/-0.01mm |

| Materials Avaiable | Aluminum alloy ADC12, ADC10, A360, A380, A356 Magnesium Alloy AZ91D, AM60B Zinc alloy ZA3#, ZA5#, ZA8# Stainless steel, Grey Iron, Steel, Brass, Bronze (Can be customized as customers' requirements) |

| Surface Treatment | Electroplating/Polishing/Powder Coating/Sandblasting/Metal Brushing/Anodizing/Electrophoresis/Shot Blasting/Phosphating/Baking Paint |

| Drawing Formats | IGES, STEP, AutoCAD, Solidworks, STL, PTC Creo, DWG, PDF, etc |

| Application | Furniture, Industry fittings and Construction and Decoration, etc. |

1. Die Casting

1. Die Casting

- High precision surface finish: Die casting produces complex shapes and thin walls.

- Efficient production: Ideal for high-volume manufacturing with automated processes.

- Limited to low-melting-point alloys: Best suited for aluminum, zinc, and magnesium.

- High initial costs: Requires significant investment in molds and equipment.

- 2. Investment Casting

- Exceptional precision surface finish: Achieves fine details and complex geometries.

- Versatile material options: Supports a wide range of metals, including stainless steel and superalloys.

- Broad size range: Suitable for both little and large parts.

- Higher costs: The process is more intricate, making it suitable for medium to low-volume production.

3. Sand Casting

- Cost-effective: Uses inexpensive mold materials, ideal for single or low-volume production.

- Flexible and adaptable: Can produce parts of almost any size and shape.

- Suitable for large parts: Commonly used for heavy machinery components.

- Rougher surface finish: May require additional machining.

- Limited dimensional accuracy: Not as precise as die casting or investment casting.

Cooperation process

1. Demand confirmation: Communicate with customers to clarify product specifications, material selection and special requirements.

2. Design and engineering: Customers provide design drawings and develop detailed production process plans.

3. Mold manufacturing: According to the design plan, molds are manufactured to ensure mold quality and service life.

4. Trial production and verification: Samples production, conduct comprehensive quality inspections and customer confirmation, and adjust the process based on feedback.

5. Mass production: Carry out large-scale production according to the optimized process flow, and strictly control the quality of each link.

6. Post-processing: Carry out necessary cleaning, heat treatment and surface treatment to improve product performance and appearance.

7. Quality inspection: Carry out comprehensive inspection of finished products to ensure that they meet customer requirements and industry standards.

8. Packaging and delivery: Packaging according to customer needs, and arrange logistics distribution to ensure safe and timely delivery.

Henan Yuanfei is one famous company in China which specialized in various metal casting products with over 10 years experience, located in China.It covers a comprehensive range of sand casting, investment casting, die casting and widely used in Agriculture machinery, Motor Vehicle, Architecture,Railway and Engineering We have a complete line of mold making, casting production, machining and assembly to meet customer requirements for finished parts. For our customers we have designed and manufactured over hundreds sets of moulds these years. Most of our products have exported to USA, Germany, Italy, U.K., Belgium , Finland and so on.

Related Products

Do you have any questions?

We will contact you within one working day. Please pay attention to your email.