Custom Lost Wax Casting Products Metal Iron Carbon Stainless Steel Precision Investment Casting Part

Construction hardware castings are used for various metal accessories in buildings. They are usually made of iron, steel, copper, aluminum and other metal materials through casting processes.For construction hardware, casting can produce parts with complex shapes and certain strength and durability.With the development of technology, modern casting technology also includes precision casting, pressure casting, centrifugal casting and other methods. Each method has its own characteristics and scope of application, and the most suitable casting process can be selected according to the requirements of specific products.

Category:

Construction Hardware Casting

key word:Die casting

I want to consult

Product Description

| Product name | Custom Lost Wax Casting Products Metal Iron Carbon Stainless Steel Precision Investment Casting Part |

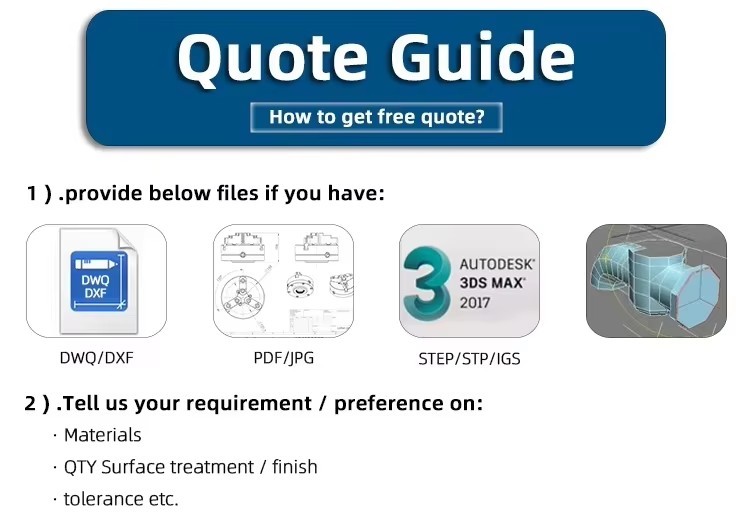

| Quotation | According to your drawing(size, material, thickness, processing content, and required technology, etc) |

| Tolerance | +/-0.01mm |

| Materials Avaiable | Aluminum alloy ADC12, ADC10, A360, A380, A356 Magnesium Alloy AZ91D, AM60B Zinc alloy ZA3#, ZA5#, ZA8# Stainless steel, Grey Iron, Steel, Brass, Bronze (Can be customized as customers' requirements) |

| Surface Treatment | Electroplating/Polishing/Powder Coating/Sandblasting/Metal Brushing/Anodizing/Electrophoresis/Shot Blasting/Phosphating/Baking Paint |

| Drawing Formats | IGES, STEP, AutoCAD, Solidworks, STL, PTC Creo, DWG, PDF, etc |

| Application | Furniture, Industry fittings and Construction and Decoration, etc. |

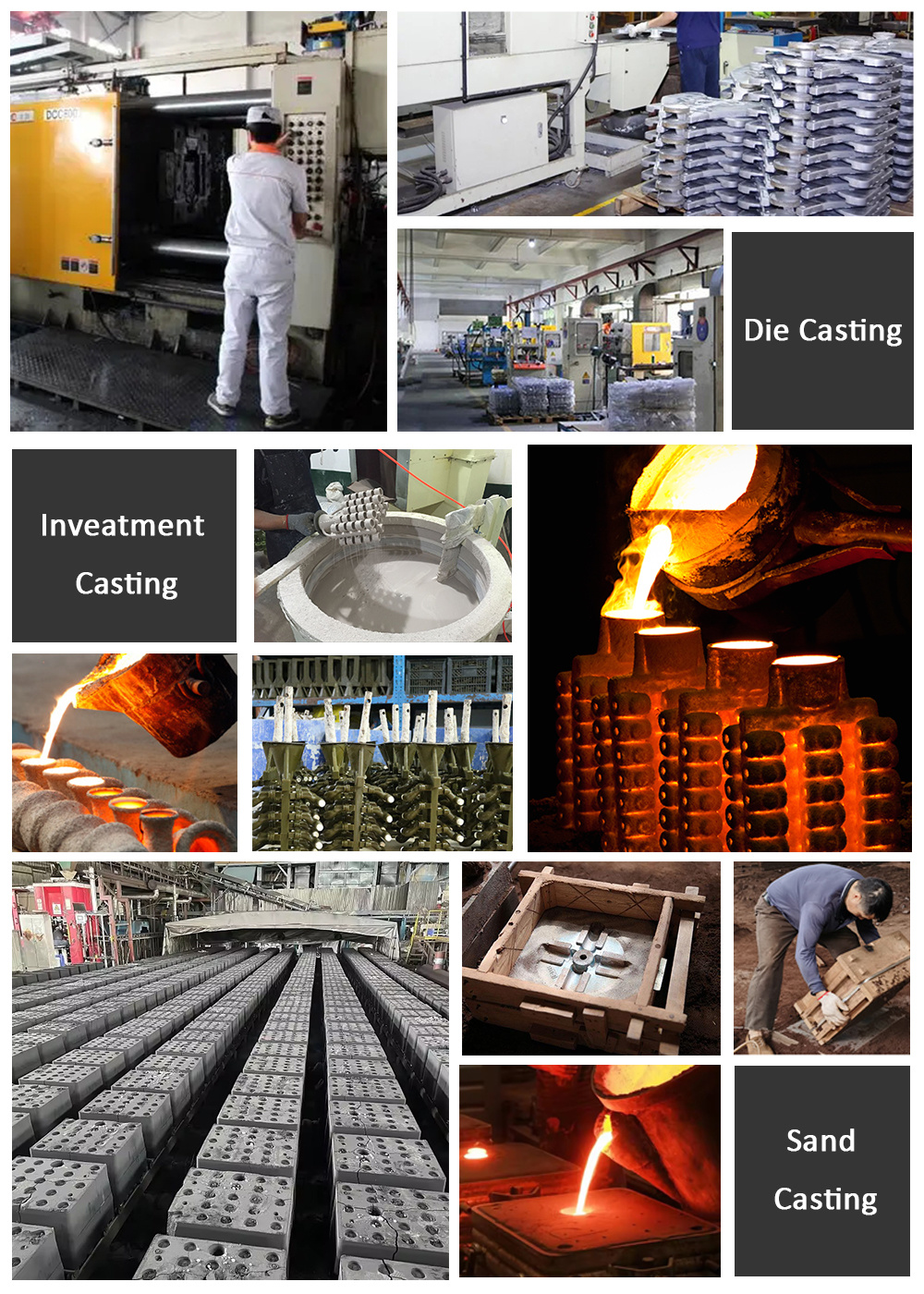

1. Die Casting

1. Die Casting

High precision: suitable for complex shapes and thin-walled parts, with a tolerance of ± 0.1 mm.

Fast speed: Automated production, suitable for large quantities.

Material limitations: mainly used for low melting point alloys such as aluminum, zinc, magnesium, etc.

High cost: The investment in molds and equipment is large, but the cost of mass production is low.

Applications: automotive parts, home appliance casings, electronic radiators.

- 2. Investment Casting

Extremely high precision: fine details with a tolerance of ± 0.05 mm.

Wide range of materials: suitable for stainless steel, nickel based alloys, titanium alloys, etc.

Complex structure: suitable for complex internal structures and thin-walled components.

Excellent quality: The castings are dense and have good mechanical properties.

High cost: The process is complex and suitable for little and medium-sized batches.

Applications: Aerospace, medical equipment, jewelry.

3. Sand Casting

Low cost: The mold is cheap and suitable for single or less quantity.

High flexibility: It can cast parts of any size and shape.

Suitable for large components: commonly used for heavy machinery parts.

Surface roughness: usually requires subsequent processing.

Limited accuracy: tolerance of around ± 1.5 mm.

Applications: Heavy machinery, agricultural machinery, valves, pump bodies.

Cooperation process

1. Preliminary communication: Understand customer needs and provide a quotation.

2. Design and Engineering: 3D modeling, process planning, mold design.

3. Sample production: trial production, quality inspection, customer confirmation.

4. Batch production: mold preparation, raw material procurement, casting production, process monitoring.

5. Post treatment: cleaning, heat treatment, surface treatment.

6. Quality control: comprehensive testing, document recording, packaging and labeling.

7. Logistics and delivery: transportation arrangement, delivery confirmation.

8. After sales service: technical support, feedback collection, maintenance and repair

Henan Yuanfei is one famous company in China which specialized in various metal casting products with over 10 years experience, located in China.It covers a comprehensive range of sand casting, investment casting, die casting and widely used in Agriculture machinery, Motor Vehicle, Architecture,Railway and Engineering We have a complete line of mold making, casting production, machining and assembly to meet customer requirements for finished parts. For our customers we have designed and manufactured over hundreds sets of moulds these years. Most of our products have exported to USA, Germany, Italy, U.K., Belgium , Finland and so on.

Related Products

Do you have any questions?

We will contact you within one working day. Please pay attention to your email.