Custom Precision Lost Wax Casting Parts Fabrication Aluminum Stainless Steel Investment Casting Foundry

Choosing appropriate materials and processes is crucial for ensuring the quality, performance, and cost-effectiveness of building hardware castings. Factors to consider include application environment, mechanical performance, aesthetic requirements, cost, etc. Before finalizing the materials and processes, it is recommended to make samples and conduct testing to verify whether they meet all expected requirements.

Category:

Construction Hardware Casting

key word:Die casting

I want to consult

Product Description

| Product name | Custom Precision Lost Wax Casting Parts Fabrication Aluminum Stainless Steel Investment Casting Foundry |

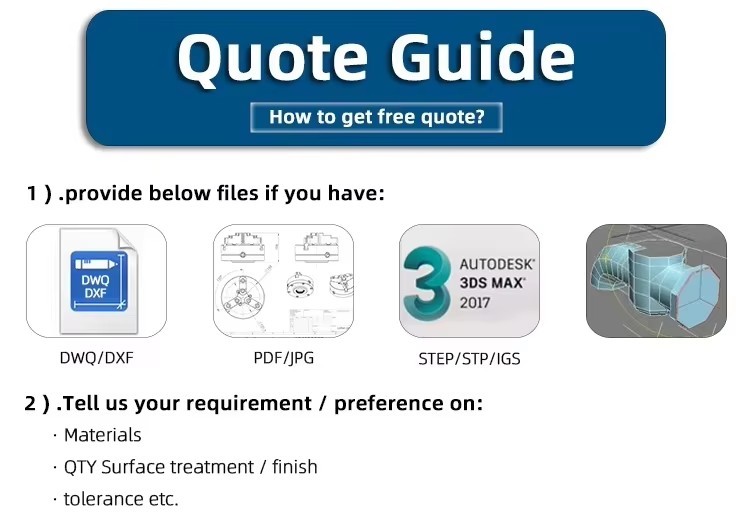

| Quotation | According to your drawing(size, material, thickness, processing content, and required technology, etc) |

| Tolerance | +/-0.01mm |

| Materials Avaiable | Aluminum alloy ADC12, ADC10, A360, A380, A356 Magnesium Alloy AZ91D, AM60B Zinc alloy ZA3#, ZA5#, ZA8# Stainless steel, Grey Iron, Steel, Brass, Bronze (Can be customized as customers' requirements) |

| Surface Treatment | Electroplating/Polishing/Powder Coating/Sandblasting/Metal Brushing/Anodizing/Electrophoresis/Shot Blasting/Phosphating/Baking Paint |

| Drawing Formats | IGES, STEP, AutoCAD, Solidworks, STL, PTC Creo, DWG, PDF, etc |

| Application | Furniture, Industry fittings and Construction and Decoration, etc. |

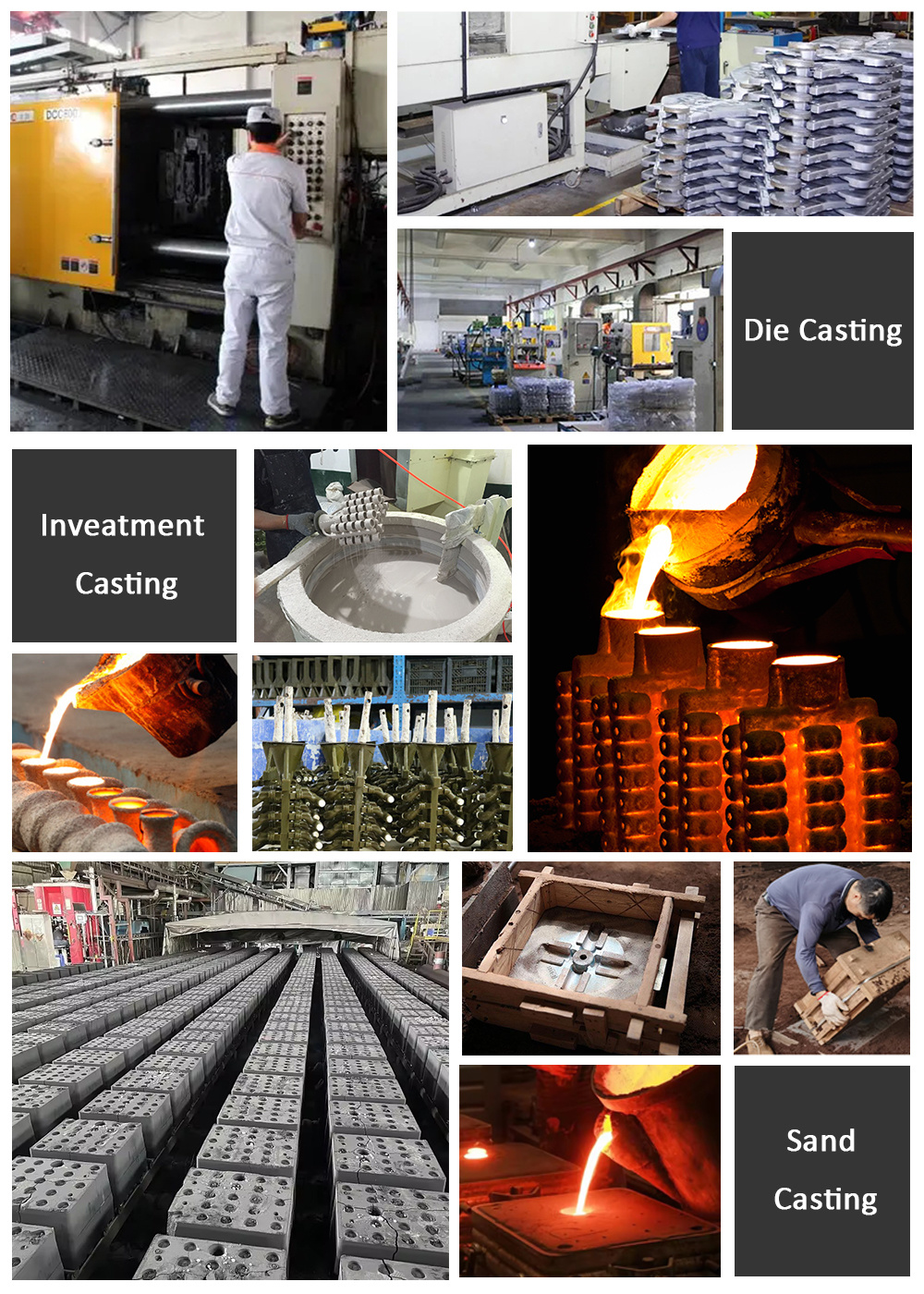

1. Die Casting

1. Die Casting

High precision: suitable for complex shapes and thin-walled parts, with a tolerance of ± 0.1 mm.

Fast speed: Automated production, suitable for large quantities.

Material limitations: mainly used for low melting point alloys such as aluminum, zinc, magnesium, etc.

High cost: The investment in molds and equipment is large, but the cost of mass production is low.

Applications: automotive parts, home appliance casings, electronic radiators.

- 2. Investment Casting

Extremely high precision: fine details with a tolerance of ± 0.05 mm.

Wide range of materials: suitable for stainless steel, nickel based alloys, titanium alloys, etc.

Complex structure: suitable for complex internal structures and thin-walled components.

Excellent quality: The castings are dense and have good mechanical properties.

High cost: The process is complex and suitable for little and medium-sized batches.

Applications: Aerospace, medical equipment, jewelry.

3. Sand Casting

Low cost: The mold is cheap and suitable for single or less quantity.

High flexibility: It can cast parts of any size and shape.

Suitable for large components: commonly used for heavy machinery parts.

Surface roughness: usually requires subsequent processing.

Limited accuracy: tolerance of around ± 1.5 mm.

Applications: Heavy machinery, agricultural machinery, valves, pump bodies.

Cooperation process

1. Preliminary communication: Understand customer needs and evaluate project feasibility.

2. Quotation: Provide detailed quotations based on requirements, collect detailed product specifications, drawings, technical requirements, quality standards, and other information.

3. Contract signing: After both parties reach an agreement on price, delivery time, payment method, etc., a formal purchase and sale contract or agreement is signed.

4. Design confirmation: Confirm the final design proposal with the client to ensure that it meets their needs.

5. Manufacturing: Casting production is carried out according to established production processes and quality control standards.

6. Quality inspection: Conduct dimensional inspection, visual inspection, internal defect detection, and performance testing if necessary.

7. Shipping: According to the customer's requirements, package the product appropriately, arrange logistics, and deliver the product to the customer's designated location on time.

8. After sales support: Provide necessary technical support and services.

Henan Yuanfei is one famous company in China which specialized in various metal casting products with over 10 years experience, located in China.It covers a comprehensive range of sand casting, investment casting, die casting and widely used in Agriculture machinery, Motor Vehicle, Architecture,Railway and Engineering We have a complete line of mold making, casting production, machining and assembly to meet customer requirements for finished parts. For our customers we have designed and manufactured over hundreds sets of moulds these years. Most of our products have exported to USA, Germany, Italy, U.K., Belgium , Finland and so on.

Related Products

Do you have any questions?

We will contact you within one working day. Please pay attention to your email.